Pedals board QT_PY SamD21 + Hx711

This board enables connecting up to 3 load cells, buttons/encoders and various sensors, to easily build your own pedal set.

Several connectors give access to various peripherals.

Most Load Cell dedicated boards on the market use a potentiometer for sensitivity adjustment, which has many drawbacks: the potentiometer is usually located at the pedals level and is therefore difficult to adjust, moreover, they may tend to get disrupted regularly, especially on a dynamic simulator. On this PB_01 board, the measurment IC for the load cell is the Hx711, which proposes 3 different digital gains. Its 24-bit ADC makes it possible to have a high accuracy while exploiting the entire range of your sensor without needing this additional sensitivity adjustment potentiometer.

Node Blue Example for 1 Load Cell and 2 potentiometers : Hx711_2A_HID

Along with the load cell, you will have access to 7 digital or analog inputs (12 bits), to connect for example additionnal potentiometers or angular hall effect sensors. The inputs are 3.3 V and are not 5 V tolerant.

Tutorials

To reprogram the board or to calibrate axis, you need to

install Node Blue and open the project installed on your board.

Gain adjustment for strain gauges A

The Hx711 has 2 inputs A and B for 2 strain gauges. Only the gain of the A channel amplifier is adjustable (64 or 128). You can also connect the same gauge on the 2 channels in order to enlarge the possible choices for the gains between 32, 64 or 128.

To choose this gain, you can:

– choose it directly in Node Blue in the parameters of the Hx711 module

– connect a digipot to choose the gain between 32 (channel B), 64 or 128 (channel A). Changing gain by using this method is not saved in EEPROM, so the system used should be absolute.

Axis Calibration

In

Node Blue, open a serial monitor on the board (at the top of the window, select the correct COM port and click on the # icon), You can see the calibration messages in the serial monitor (window at the bottom in

Node Blue).

Click on the "Cal" entry of the "X", "Y" or "Z" calibration module. The message "Set to min position" is displayed.

Position the axis to the minimum (or a little more), and click again on the "Cal" entry: The message "Set to max position" is displayed.

Position the axis at the maximum (or a little less), and click again on the "Cal" entry: The message "Calibration finished" is displayed.

The calibration is finished, repeat the process for the other axes if necessary. The settings are saved in the EEPROM of the card and restored at each restart.

To clear the calibration data, go to the "Settings" menu of

Node Blue, check "Clear Storage" and upload your project 2 times in a row.

How to find the wiring for a 4 wire strain gauge

The colors of the wires are not standardized, so to determine which wire corresponds to which function, most of the time it is sufficient to measure the resistance between each pair of wires.

Take 2 wires and measure the resistance between them with a multimeter. Keep only one of the 2 wires, choose another wire, and measure the resistance again. The pair of wires which has the greatest resistance will be taken for the excitation of the gauge (E+ and E-), the 2 other wires (which should have the same resistance as E+ and E-) will be taken for the measurement (A+ and A-).

Explanation :

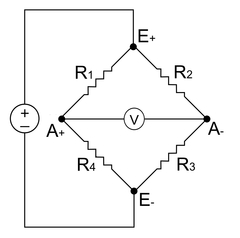

A strain gauge is a Wheatstone bridge:

An excitation voltage is applied between E+ and E- and the voltage V between A+ and A- is measured, which varies when one or more resistors change. On a strain gauge the resistances vary when the gauge is deformed under the effect of a force.

In practice most of the time the resistances are equal to each other.

So if R=R1=R2=R3=R4, we will measure only 2 possible resistances between the wires: the one between E+ and E- or A+ and A- which will be the largest and which will have the value R, and the one between E+/A+, E+/A-, A+/E- or A-/E- which will be the smallest and which will have the value 0.75xR 1/(1/R + 1/(3xR)).

So whatever the combinations of wires to measure the resistance, you will only find 2 possible resistances, the smallest having the value of 3/4 of the largest one.

Once the pairs have been found, they can be inverted because the circuit is perfectly symmetrical (E+/E- instead of A+/A-). The measurement voltage will be positive for a force applied in one direction, and negative for the other direction. Please note that the gauges generally have an arrow to indicate in which direction the force should be applied. Analog to digital converters used to measure voltage are typically used in differential mode, so polarity doesn't matter, but if it does, you can invert the measurement voltage by swapping the leads on the measured part.

Wiring

nodeblue

file=examples/Boards/QTPySamD21/QTPYSamD21_Hx711_2A.txt

scale=0.75

type=wiring

interactive=false

There are no reviews yet.